Submission 2024

| Submitted by: | Mohamad Ghadban |

| Department: | Mechanical Engineering |

| Faculty: | Engineering |

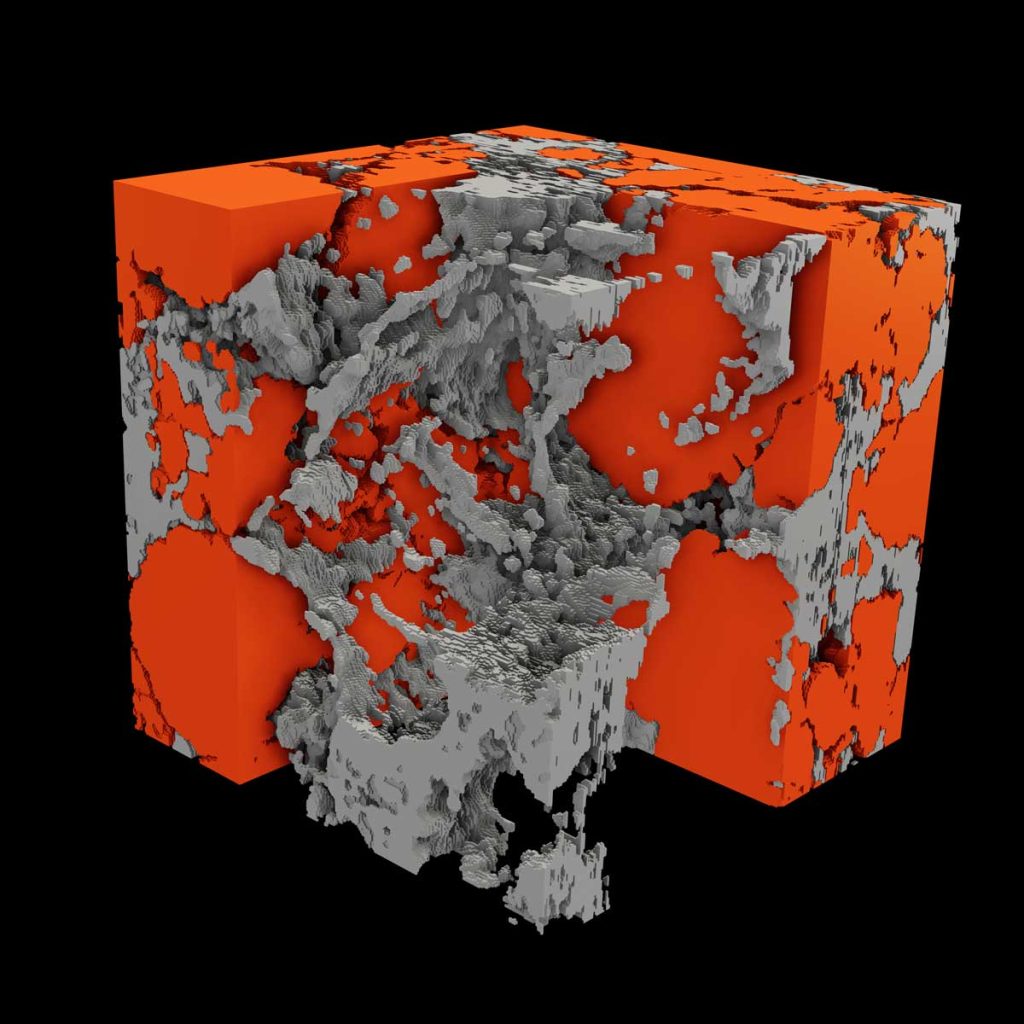

To understand a phenomenon, we have to dive deep into it to get as many details as we can about it. This is especially true in the energy technology field where lithium-ion batteries (LIBs) are ubiquitous. The performance of LIBs, however, is still not optimal where it could be improved in terms of durability, safety, and cost. It is primarily determined by the physical phenomena that occur at very small length scales inside the battery. The image shown represents the marvelous internal structure of a LIB cathode electrode, a necessary component for the LIB operation. In the battery world, we refer to this structure as the “microstructure” because it has a size of a few micrometers which is roughly equivalent to the diameter of a human hair. The microstructure is composed of active material (red) that stores lithium, conductive binder material (gray) that allows electrons to flow through and binds everything together, and pores (holes) that hold the electrolyte. In my research, I study the impact of the arrangement of the cathode materials on the LIB performance by analyzing its microstructure, and I try to come up with an optimal arrangement that maximizes its performance.

Was your image created using Generative AI?

No.

How was your image created?

To create the 3D microstructure, 2D image slices with 50 nm pixel resolution were obtained for a lithium-ion battery (LIB) cathode using Focused Ion Beam Scanning Electron Microscopy. The obtained raw grayscale images contained artifacts, so I filtered the images to remove the unwanted noise. Then, I enhanced the contrast of the images and segmented them using a tool called Fiji. Given that the enhanced images were still in grayscale mode, segmentation allows the identification of objects in grayscale images. This latter step allowed me to represent the identified objects using numerical data structures. Filtering and segmentation were applied to 300 different slices representing the LIB cathode. Then, all images were stacked on top of each other using an algorithm developed in our lab to create the 3D microstructure shown. To visualize it, I used a program called Paraview which allows the representation of different materials using different colors. I use 3D microstructures to run numerical simulations and visualize the physical phenomena occurring at such small scales to be able to optimize the performance of the LIB by analyzing the arrangement of the cathode constituents.